Rodney Brooks, famous for his pioneering work of creating insectoid robots at MIT, Massachusetts Institute of Technology, Cambridge, USA, and later by the success of domestic robots from the iRobot Company that he co-founded, simply needs to do new things, like any creative mind. Now, through the new company Rethink Robotics, is developing robots that can adapt to work in manufacturing and factory environment, working safely with people and showing “common sense”.

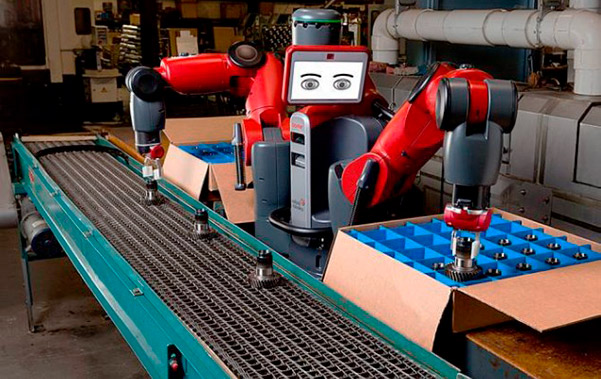

The first commercial model of Rethink, Baxter, in production for a few months, is a two-armed robot with a human likeness, that can be programmed to learn repetitive production work, such as handling, testing and classification of components, assembly thereof (except if they weigh too much), packing and unpacking. Everybody, although he doesn’t know very much about technology, can program Baxter, just using its simple strategy for moving its arms, and pressing buttons on a control panel to complement programming.

Baxter’s “face” (eyes and eyebrows shown on an LCD display) indicates its status and where is paying attention (the direction of its “look”). In its “head” there are sensors that recognize when people are nearby. In his joints there are sensors to reduce the impact force if it detects a collision.

The good ability of Baxter to perceive the proximity of people and its capacity to avoid accidentally harming them, it’s a great advantage, most of all if it’s compared with more primitive industrial robots, that are potentially more dangerous.

Baxter’s design was not made exclusively from a laboratory, but also from an extensive observation in factories. This practical experience led Brooks and his colleagues to discard many items for Baxter that, at first, seemed useful, as a voice interface (because factories are noisy) or a touch screens (because many workers wear gloves).

Once decided the basic design, Brooks’ team began reducing manufacturing costs, replacing expensive mechanical components with more sophisticated software. In fact an advanced program allows the robot to rectify mechanical irregularities, such as problems with gears. Relatively simple items such as cameras help the robot to detect objects accurately without a motor precision that is instead essential to the typical industrial robots, for grasping objects without seeing them.

Robot hardware has some impressive qualities. A key component (which allows the robot to perceive and soften collisions) was invented and patented at MIT: Baxter arms have a mechanism that was invented by Gill Pratt, before MIT, and Matt Williamson, who was once a student of Brooks.

If we want to see parallels between Brooks’ work for iRobot and his work to Rethink Robotics, we could say that the design philosophy of Baxter will lower costs and extend industrial robots as it has been done in the case of Roomba (the famous robot vacuum) and other similar robots from iRobot and other companies for the growing domestic robotics.